GALVABOND® Sheet and Coil Products Supplied and Processed by Coil Steels

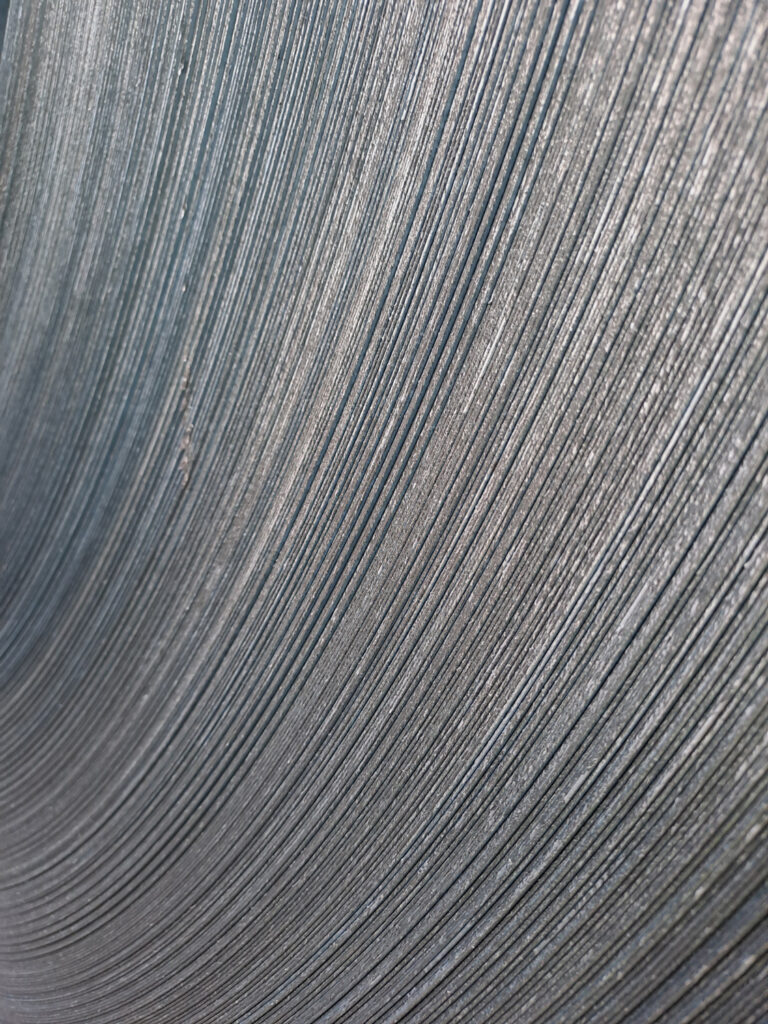

Commonly used in commercial and general manufacturing applications, GALVABOND® steel is widely recognised for its appealing spangled surface. GALVABOND® steel offers guaranteed minimum elongation properties and is designed for forming and moderate drawing applications. Available in two grades including G2 and G2S, GALVABOND® steel is produced using a continuous hot dip zinc-coating process with a range of different coating classes.

The product is suitable for moderate drawing applications and is suitable for lock seaming up to 1.6mm thick. GALVABOND® steel G2S is skin passed to improve surface quality. Under normal storage conditions, free of fluting for 3 months after galvanising. GALVABOND® steel products are available in a range of thickness options – conforming to relevant Australian Standards AS/NZS 1365:1996 (R2016) and AS 1397:2021.

GALVABOND® steel is used in the manufacture of many products, such as partition walling systems, air conditioning ducts and panels, tube, meter boxes, trailers, cable trays, scaffolding planks, rendering mesh, and feeder troughs. With Coil Steels, customers can source all their GALVABOND® steel sheet and coil products to suit their project needs.

Offering the following key benefits, GALVABOND® steel supplied by Coil Steels and made locally by BlueScope:

- Coating

GALVABOND® steel is coated with a layer of zinc, which provides excellent corrosion resistance. The zinc coating acts as a protective barrier, preventing the underlying steel from coming into direct contact with moisture or corrosive elements. - Durability

The zinc coating enhances the durability of GALVABOND® steel, making it highly resistant to rust and corrosion. This makes it a suitable choice for outdoor applications, where the material is exposed to environmental elements such as rain, humidity, and saltwater. - Formability

GALVABOND® steel maintains its formability even after the zinc coating process. It can be easily bent, shaped, and formed without compromising the integrity of the coating. This makes it versatile and suitable for various manufacturing processes, including roll forming, bending, and welding. - Cost-Effectiveness

GALVABOND® steel offers cost-effective protection against corrosion. By applying a zinc coating to the steel, it significantly extends the lifespan of the material, reducing the need for frequent maintenance and replacement. This can result in long-term cost savings, especially in applications exposed to harsh or corrosive environments. - Sustainability

GALVABOND® steel is a sustainable choice due to its durability and recyclability. The zinc coating can be recycled and reused, reducing the environmental impact of the material. Additionally, the extended lifespan of GALVABOND® steel means less frequent replacements, further reducing waste.